emergency blow systems

Based on customer’s specification we develop a system that fully achieves the flow and pressure requirements, we build it in our own workshop and test it in our unique test facility. SAB has for decades developed and in use different Emergency De-Ballasting Systems on submarines. Based on our experience we are happy to advise navies and shipyards during implementation on board and habour and sea trials.

Background information

If a problem occurs on a submarine whilst submerged a fast, secure surfacing of the boat is required and the on-board Emergency De-ballasting System EBS will be actuated. By actuating the EBS large amounts of air/gas will be transferred into the Main Ballast Tank (MBT) forcing the water out of the tank thus lowering the weight of the submarine and bringing it quickly to the surface.

During the emergence of the submarine the following things are crucial and have to be taken into the build calculation:

• The submarine should emerge as quickly as possible

•The overpressure of the MBT shall not damage the tank

•The emerging angle of the submarine shall be in the limits of the submarine design

•A possibility to stop emergence is desirable

At the start of the blow cycle the pressure in the MBT will raise, a gas bubble then builds up allowing the water in the MBT to start to move out of the tank, at this stage the pressure will begin to stabilise and the boat will rise. Due to the natural expansion of the air/gas in the MBT during the ascent of the boat, pressure will increase again causing the boat to rise further allowing the pressure to begin to slowly drop off.

State of the art

Over the years rocket boosters offering a high emerging speed have been used but these are very expensive to purchase/install and allow no possibility for follow on system training or testing. The cost efficient option is to use readily available High Pressure (HP) air to operate the system which ensures that on-board training and testing are easily achieved throughout the life of the boat. In HP air driven EBS the main valves used are single stage slow opening blow valves, single stage fast opening regulators or two stage controlled blow valves.

TWO STAGE CONTROLLED BLOW OFF VALVE

The two stage controlled blow valve ensures a very safe operation where very high flows are achieved.

The two stage controlled blow valve consists of a pneumatically actuated throttle valve for the first stage and a pneumatically opened stop valve in the second stage. The size of the 1st stage (10-25mm Dia) will be significantly smaller than the size of the 2nd stage (50-100 mm Dia).

Actuation of the emergency blow valve by means of compressed air will open the 1st stage slowly allowing for the build-up an air bubble in the ballast tank and start the flow of water out of the ballast tank. The 1st stage remains open for the rest of the blowing process. Once the maximum allowable differential pressure between ballast tank pressure and external seawater pressure is reached the 2nd stage will be closed. The second stage, which is operated by means of a mechanical / pneumatic control unit, will open again at a pre-set differential pressure. The control unit can be integrated in the emergency blow valve.

Other options available within the design are for a second integrated control unit which will close the second stage when blowing in shallow depths, a manual override and a position indication/transmission operated by indicators/limit switches.

SINGLE STAGE SLOW OPENING BLOW VALVE

Single stage slow opening blow valves are adapted to the customer’s requirements in terms of flow, size, dimensions and opening time. For these types of valves a correct setting of the flow curve is very important to avoid any over pressurization of the MBT.

SAB has successfully supplied over the years several types of single stage slow opening blow valves to customers all over the world.

The system valves can be located inside the submarines hull or in the ballast tanks and can be equipped with a manual override. Depending on customer’s requirements they can be equipped with throttle valves, hydraulic dampening systems, etc.

SAB’s emergency blow valves can be fitted with double, redundant actuation pistons in order to allow actuation from different parts of the submarine. The monitoring of this can be done by means of limit switches.

SINGLE STAGE FAST OPENING REGULATING BLOW VALVE

The single stage regulating blow valve works on the principle of a pressure reducer, regulating the outlet pressure to prevent overpressure in the MBT. The single stage fast opening regulating blow valve works on the principle of a pressure reducing valve by regulating the outlet pressure to a set value above the differential pressure; (i.e.) 1,0 bar above the differential pressure between ballast tank and external seawater depth pressure. The control valve core evaluates the pressure control lines of the ballast tank and the seawater depth. The emergency de-ballasting procedure is controlled by a combined mechanical /hydraulic/pneumatic system. This element will control the pressure in the MBT irrespective of the actual diving depth, the level of water in the ballast tank and the available flow of compressed air. In order to meet with this requirement, the control valve core is equipped with a pressure balanced piston.

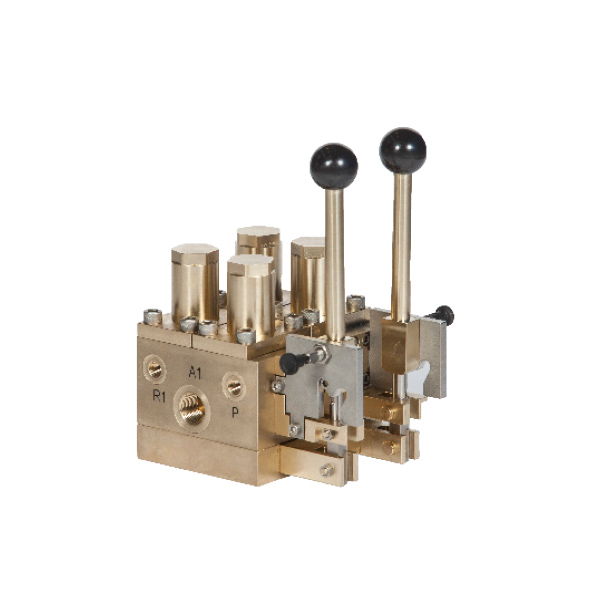

ACTUATION VALVES

The actuation of the EBS can be achieved in four different ways. The method required will be dictated to SAB by the submarine design team or, as is the norm, jointly between SAB and the submarine design team. They can be either one of the following methods or a combination of any of them. There are four methods available which are low pressure air, high pressure air, electrical or hydraulic. The SAB recommendation for all submarines is for compressed air actuation as compressed air is readily available on-board. SAB have concerns if a purely electrical/hydraulic actuation is installed as it would fail in the event of an electric/hydraulic submarine system break down. As an extra precaution SAB could integrate the EBS to the ships control system with the provision of an electro/pneumatical actuation using a combined 3/2 way manual/solenoid valve. In this case the EBS will be actuated by the solenoids in normal operation and by hand in case of electric failure. The electrical system can be fitted to fail safe to ensure the valve remains open even with a signal failure during operation.

Components

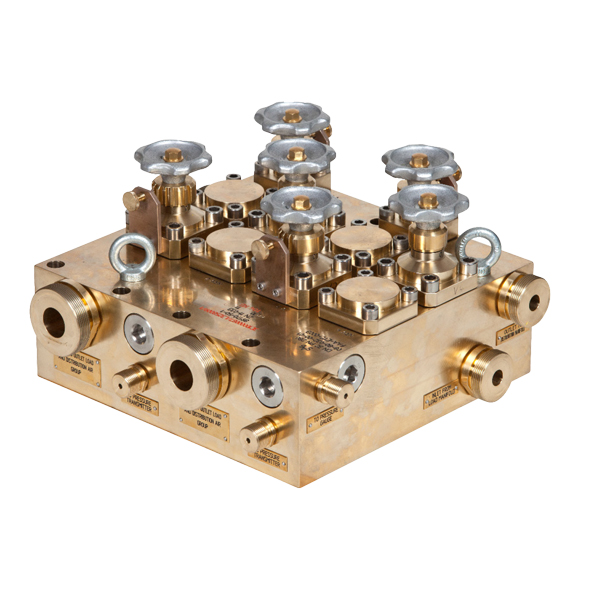

Hull valves are used as the connection to the cylinders, the ballast tanks and the external sea water entrance/exit. They are of a cartridge design based on the “Kingston Principle” which includes a non-return function if the event of damage to the valve internals. The SAB ergonomically improved hull valves are of low torque and can be manually operated. Manifolds for the connection of HP Air and LP Air to the EBS which include both valve installed manifolds and plain connection manifolds. The valve manifolds can be equipped with any SAB standard valve or filter as well as the SAB PED approved safety relief valves.

Pressure reducing stations are designed and manufactured to the customer’s requirements.

TEST FACILITY

SAB has a full in-house test facility which includes the equipment required for the complete test of the EBS. The test takes into account full strength, tightness, functional and flow tests. It operates at pressures up to 400 bar and flows higher than 50 kg/s.

The flow test facility consists of a 400 bar compressor unit, a cylinder bank allowing for 2400 litres, a tank with exchangeable throttles that simulates the MBT and a highly efficient silencer. It is monitored to save all the relevant data (flows, temperatures, pressures) electronically. The system is designed to meet all current safety regulations.

Our experience has enabled SAB to design, manufacture and supply full EBS testing equipment to navies and shipyards worldwide. SAB can work with any end user to design and supply on their behalf full test equipment including a water system that replicates a real emergency blow of a submarine.